Understanding Industrial Vacuum System Design for Optimal Business Efficiency

Industrial vacuum systems are crucial components in various industries, facilitating efficient material handling, dust collection, and environmental control. As businesses strive for efficiency and productivity, the significance of a well-designed industrial vacuum system cannot be overstated. This article delves deep into the design of industrial vacuum systems, highlighting their importance, components, benefits, and considerations for creating a robust system that optimizes business operations.

What is Industrial Vacuum System Design?

The term industrial vacuum system design refers to the engineering and planning processes involved in creating vacuum systems specifically tailored for industrial applications. This involves selecting appropriate components, determining the layout, and ensuring the system meets operational requirements.

Key Components of Industrial Vacuum Systems

Understanding the individual components of an industrial vacuum system is vital for effective design. The main components include:

- Vacuum Pumps: The heart of any vacuum system, these devices create the vacuum necessary for material handling.

- Filters: Essential for ensuring that particles don't escape into the environment, filters maintain the cleanliness of the system.

- Piping: This includes all the hoses and ducts that transport materials within the system.

- Control Systems: These systems manage the operation of the vacuum, adjusting power and airflow as needed.

- Collection Containers: These are used to store the vacuumed materials until they can be disposed of or reused.

Benefits of Effective Industrial Vacuum System Design

The design of industrial vacuum systems plays a critical role in achieving various operational benefits. Here are some compelling reasons to invest in a high-quality vacuum system:

1. Improved Air Quality

One of the most significant advantages is the enhancement of air quality within the working environment. By efficiently removing dust and particulate matter, industrial vacuum systems contribute to a healthier workplace, reducing the risk of respiratory issues among employees.

2. Increased Operational Efficiency

Properly designed vacuum systems streamline material handling processes. This reduces downtime and increases productivity, as workers can focus on their tasks without frequent interruptions from material removal.

3. Cost Savings

Investing in an efficient vacuum system can lead to long-term cost savings. By minimizing waste and optimizing resource use, businesses can significantly cut down operational costs.

Factors to Consider in Industrial Vacuum System Design

Designing an effective industrial vacuum system requires a comprehensive understanding of various factors that influence performance:

1. Application Requirements

Different industries have unique requirements. For example, food processing facilities may require systems that comply with strict hygiene standards, while manufacturing plants might need heavier-duty systems for large debris removal. Tailoring the design according to application is paramount.

2. System Size and Capacity

Determining the right size and capacity is essential. An undersized system will struggle to cope with demand, while an oversized system may be wasteful and inefficient. Careful calculations based on expected material load are necessary.

3. Environmental Regulations

Compliance with environmental regulations is critical in industrial settings. The vacuum system design should ensure that it meets local and international standards concerning emissions and waste disposal.

Types of Industrial Vacuum Systems

With a variety of industrial vacuum systems available, selecting the right type for specific applications is crucial. Here's an overview:

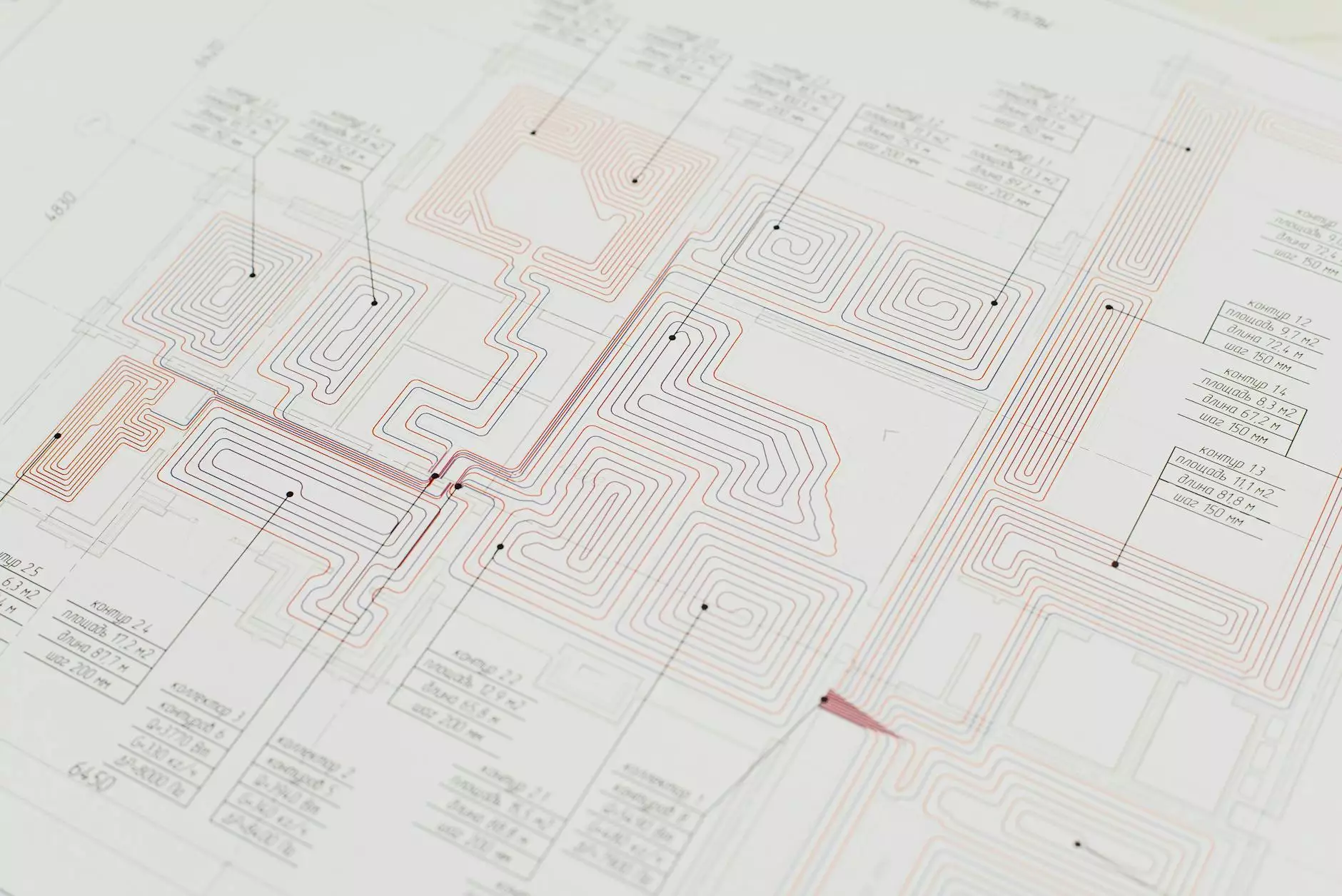

1. Centralized Vacuum Systems

These systems are designed for performance in large facilities. They consist of a central vacuum source connected to various points in the building via a piping network. Centralized systems are ideal for continuous, heavy-duty applications.

2. Portable Vacuum Systems

For smaller operations or specific tasks, portable vacuum systems provide flexibility and ease of use. They can be moved to different job sites or areas within a facility, offering convenience for localized cleaning needs.

3. Stationary Vacuum Systems

Stationary systems are built for fixed installations and are often integrated into production lines. These systems feature powerful suction and are suited for continuous operation, making them perfect for high-volume applications.

Designing an Effective Industrial Vacuum System

When embarking on the design of an industrial vacuum system, a systematic approach can yield the best results. Here’s a step-by-step guide:

1. Assess Needs and Scope

Understanding the specific needs of your business is the first step. Analyze the processes that require vacuuming and identify any unique challenges you may face.

2. Choose Appropriate Components

Based on the assessment, select vacuum pumps, filters, and other components that match your operational requirements. Consult manufacturers for advice on compatible systems.

3. Develop a Layout Plan

Design a layout that optimizes space and efficiency. Ensure that the piping routes are clear and that the system can be easily maintained.

4. Regulatory Compliance

Before finalizing the design, ensure that it complies with all relevant regulations and standards to avoid legal issues and fines.

5. Testing and Implementation

Once the system is installed, conduct comprehensive testing to ensure it operates as intended. Monitor performance metrics and make adjustments as necessary.

The Future of Industrial Vacuum System Design

The future of industrial vacuum system design looks promising with advancements in technology. Smart systems that integrate IoT (Internet of Things) capabilities are increasingly common. These technologies enable real-time monitoring and remote control, allowing businesses to optimize their operations proactively.

Integrating Automation

Automation in vacuum systems can lead to higher efficiencies and reduced labor costs. Systems capable of autonomous operation can adjust to varying operational conditions, further enhancing productivity.

Sustainability Considerations

As businesses shift towards sustainability, vacuum systems designed with eco-friendly technologies will become more prevalent. This includes systems that use less energy and reduce waste generation.

Conclusion

In conclusion, the design of industrial vacuum systems is crucial for enhancing business efficiency and productivity. Understanding the components, benefits, and factors involved in industrial vacuum system design empowers businesses to make informed decisions that promote a healthier work environment and improve operational performance.

Emerging technologies and sustainable practices are shaping the future of these systems, making them smarter and more efficient. Implementing a well-designed vacuum system not only meets immediate operational needs but also positions businesses for long-term success in an ever-evolving industrial landscape.